by William Ball

If you use a personal safety gas detector in your job, you need to be aware that taking a few seconds to perform a bump test every day could mean the difference between going home to your family at the end of the workday and becoming another industrial workplace fatality.

The National Institute forOccupational Safety and Health(NIOSH) estimate that millions of workers globally may be exposed to hazards in confined spaces, and every year a large number of those workers become workplace fatality statistics. Those killed include not only the individuals working in a confined space, but frequently those who attempt to rescue them. Confined spaces are encountered in a wide variety of industries including:

Sewers, underground cable vaults, tanks/vessels, silos and aircraft wings are easily identified as confined spaces. Others may not be so obvious, for example open topped chambers, vats, manure pits, unventilated or poorly ventilated rooms.

Global confined space statistics show that the majority of confined space fatalities result from hazardous atmospheric conditions. In Australia it is estimated that in 75% of confined space accidents the atmosphere was not tested prior to entry. A lack of proper training and understanding the inherent hazards are key contributing factors to confined space accidents. Awareness of potential hazards is essential to any confined space safety program and testing the atmosphere with an appropriate, properly functioning, safety gas detector is the only way to determine whether it is safe to enter.

After a confined space has been cleared for entry it is essential to monitor continuously while workers occupy the space. Atmospheric conditions can change without warning! Work activities in confined spaces such as welding, painting and degreasing, to name a few, can produce dangerous atmospheric conditions. Atmospheric hazards can also come from sources outside of the confined space. Many atmospheric gas hazards are colourless and odourless so monitoring with an appropriate safety gas detector is essential to protecting workers.

Everyday workers around the world trust their portable safety gas detector to warn them of possible life threatening atmospheric gas hazards, often with little understanding of how these important pieces of safety equipment work. Serious injury or death can be caused by exposure to toxic gases, oxygen deficient environments or explosions caused by the presence of combustible gases.

Portable gas detectors can contain various types of sensor technologies with different detection principles. The most common configuration in a confined space entry gas detector includes sensors for the detection of oxygen concentration and the presence of hydrogen sulphide, carbon monoxide and combustible gases. Workplace environments can be harsh and gas detectors are subjected to all kinds of conditions that can affect their operation. Instruments can be physically damaged, sensor ports can become obstructed by dirt and oils, sensors can be damaged by exposure to gas concentrations that exceed their detectable limit, and sensors can be exposed to compounds in the atmosphere that can degrade their performance.

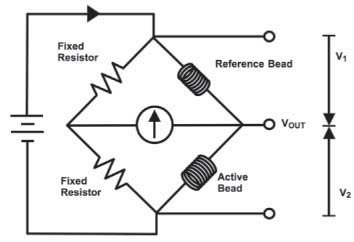

The catalytic hot bead combustible sensor used in many safety gas detectors is particularly prone to damage by compounds that can be encountered daily in the workplace environment. This type of combustible gas sensor contains two coils of very fine platinum wire coated with a ceramic or porous alumina material to form refractory beads. The beads are connected to opposing arms of a balanced Wheatstone Bridge electrical circuit. One bead (active) is additionally coated with platinum or palladium, which enables catalytic oxidation of combustible gases at concentrations below the lower explosive level(LEL) to occur. The opposing bead (reference) is identical in structure except it has been poisoned so that catalytic oxidation cannot occur.Both beads are heated to a specific temperature and in normal air, the Wheatstone Bridge circuit remains balanced. If a combustible gas is present, catalytic oxidation will heat the active bead to a higher temperature than the opposing reference bead, unbalancing the electrical resistance in the Wheatstone Bridge circuit. The difference in the electrical resistance of the active bead versus the reference bead is proportional to the concentration of combustible gas in the atmosphere.

One of the limitations of this catalytic bead technology is that the sensor is potentially prone to damage through exposure to airborne contaminants capable of impairing sensor performance, or permanently destroying the sensor. Some airborne substances can decompose on the active sensor bead catalyst and form a solid barrier over the catalyst bead surface, effectively poisoning the sensor. Silicone vapours are the most commonly encountered workplace substance capable of destroying catalytic bead sensors. Many commercially available lubricants, rust inhibitors, adhesives and cleaners contain silicone based compounds. Some other poisons to be aware of are compounds containing lead, sulphur or phosphates and high concentrations of combustible gases. A single exposure to a high concentration of a sensor poison can destroy the catalytic bead combustible sensor, or sensors can lose sensitivity gradually as a result of chronic exposure to contaminants

Automated systems make bump testing and calibration as simple as the push of a button.

Halogenated compounds such as chlorinated hydrocarbons and chlorofluorocarbons are absorbed by the active sensor catalyst inhibiting the sensor response. Exposure to these compounds is typically temporary and once the detector is removed from the contaminated environment the sensor will recover normal sensitivity. In some cases,chronic exposure to inhibitors will permanently damage the catalytic bead combustible sensor.

Electrochemical sensors used for the detection of toxic gases such as carbon monoxide and hydrogen sulphide are not as prone to poisons as the catalytic bead sensor, but their performance can also be compromised by certain ambient contaminants. Many electrochemical sensors can be temporarily or sometimes permanently damaged by exposure to organic solvents and alcohols. Methanol, which is often widely used in many parts of the world during the cold winter months,can have a profound effect on CO and H2S sensors. Many insect repellants contain alcohol and use hydrocarbons such as propane or butane as an aerosol propellant. Both can affect personal gas detector sensors. High concentrations of solvents can also affect internal components of electrochemical toxic and oxygen sensors resulting in permanent damage.

Unfortunately, even though the gas detector performs diagnostic checks at start up and during operation, it is often not possible to electronically detect a problem with sensor response. The detector cannot warn users that sensor ports are obstructed by dirt, oil, or some other substance, the capillary pore of an oxygen sensor is blocked, or the catalytic bead of a combustible sensor has been poisoned. A personal safety gas detector cannot properly protect a worker if gas molecules cannot get into the sensor or if the sensors ability to detect the target gas has been compromised.

The only way to confirm that a gas detector is functioning, and is capable of responding to gas, is to expose the instrument to a concentration of target gas high enough to initiate an alarm situation while the instrument is in operating mode. This procedure is often referred to as performing a bump test and it is a key to the safe use of portable safety gas detection equipment

At a minimum follow the safety gas detector manufacturer’s recommendations for bump testing and calibration frequency. Additional testing of a gas detector should also be performed if a detector has been subjected to any of the following circumstances:

In the evolution of safety gas detection instrumentation bump testing is a relatively new practice. Calibration of gas detection equipment is part of routine maintenance. There was a time when manufacturers recommended frequent, even daily calibration, but as sensor technology and sensor performance became better understood, the frequency lengthened. As calibration frequency decreased it was just assumed that a detector was operating properly between calibration intervals. Today, although recommended calibration frequency may vary considerably from one safety gas detector manufacturer to the next, there is unanimous agreement amongst manufacturers that it is necessary to bump test detectors between calibrations. Again, there is no manufacturer consistency in the wording of the bump testing recommendation found in gas detector manuals.Gas detector users cannot be blamed if they are confused and do not understand why bump testing is necessary. As a result the practice is often not adopted and in some areas of the world bump testing personal gas detectors between calibration intervals is virtually unheard of.

The concept of a bump test is to verify the detector sensors respond to a target gas and that the detector alarms activate. This is sufficient for many users, but others perform a calibration check, confirming the accuracy of sensor response while testing.

Sensor calibration adjusts response accuracy and bump testing verifies sensor response between calibration intervals. Performing a bump test takes only seconds and provides gas detection users with confidence that the detector about to be used is working. Be sure to use test gas from a reliable source, and check the expiry date on the cylinder. If a detector does not pass the bump test protocol do not use it. Additional testing should be done to diagnose the cause.

With the development of automated calibration and bump test systems, the process can be as easy as pushing a button. Many automated systems keep a permanent record of each test performed so that in the event of an accident investigation detailed proof of proper maintenance and testing can be easily produced. Records of manual calibration and bump testing must also be kept. Remember, if it isn’t recorded, it wasn’t done!

Increased safety awareness and improved safety practices do make a difference. According to the U.S. Department of Labour, industrial fatalities in 2006 were at the lowest rate since the fatality census began in 1992. In 1992 the number of fatal work injuries per 100,000 workers was 5.2; in 2006 the figure was down to 3.9. In Britain the same trend in workplace fatalities is evident. Since the introduction of the Health and Safety at Work Act in 1974 work related deaths have decreased approximately 35%. In 2005/2006 the number of fatalities was at the lowest level ever recorded. Fewer fatalities are the result of increased awareness and improved safety practices.

Most confined space deaths that result from exposure to lethal atmospheric conditions could have been prevented. Implement an effective confined space entry program and use appropriate safety equipment. Most atmospheric gas hazards are imperceptible to human senses, so testing the atmosphere prior to entry and continually monitoring for changes in conditions using a properly working personal safety gas detector is essential to keeping workers safe. As a minimum requirement, bump testing a safety gas detector prior to each days use should be part of any effective confined space entry safety program.

If you have questions about any of our gas detection products or services, please don’t hesitate to contact us. Whether you need a hand finding a new product or need help with your current system, just ask our team of Factory Trained Experts.